In today's interconnected global economy, productivity stands as a cornerstone of prosperity. It is defined as the ratio of output per worker per unit of time, a metric that drives higher wages and living standards. Yet, since the 2008 Global Financial Crisis, an enigmatic slowdown has emerged, leaving experts puzzled and economies strained.

This phenomenon, known as the productivity puzzle, represents an unexplained decline in growth rates across advanced nations. For instance, in the United States, labor productivity growth has dwindled to a mere 0.6% annually since 2011, casting shadows over future economic resilience. Understanding this puzzle is not just an academic exercise; it is a practical imperative for businesses and policymakers alike.

At its heart, productivity measures how efficiently inputs like labor and capital transform into goods and services. Total Factor Productivity captures gains from innovation and technology, yet these advances have stagnated in recent years. The challenge now is to reignite growth while systematically minimizing waste, a task that requires both insight and action.

Historical Trends and the Data Behind the Puzzle

The productivity slowdown is not a fleeting issue but a persistent trend. Historical data reveals a stark contrast between pre-crisis vigor and post-crisis lethargy.

In the US, for example, business sector productivity showed negative quarter-over-quarter growth for three quarters in 2015 and early 2016. This pattern echoes across other advanced economies, where IMF reports highlight a decade-long decline.

Even in sectors like agriculture, technology has reshaped labor dynamics. US farm productivity soared through innovation, reducing labor's share to under 2% while boosting food output. However, broader economic factors, such as slowed capital stock growth, contribute significantly to the puzzle.

Unraveling the Explanations

Economists propose multiple, overlapping factors for the productivity puzzle, with no single cause dominating. These explanations blend demand and supply issues, reflecting the complexity of modern economies.

- Measurement Issues: Output may be undercounted, especially with free digital services and intangibles.

- Slow Investment: Capital per worker grows slower as depreciation outpaces new additions.

- Composition Effects: Shifts to lower-productivity sectors or jobs dampen overall growth.

- Labor Market Factors: Labor hoarding by firms, enabled by weak wages, reduces efficiency.

- Institutional Rigidity: Lack of incentives for change hinders innovation adoption.

- Solow Paradox: Technology investments yield delayed productivity gains without process changes.

- Other Factors: Credit rationing, low R&D, and public sector inefficiencies add to the slowdown.

Leading firms like Elmos thrive by combining tech adoption with organizational shifts. In contrast, laggards fall behind, widening the productivity gap. This diversity of causes underscores the need for tailored solutions.

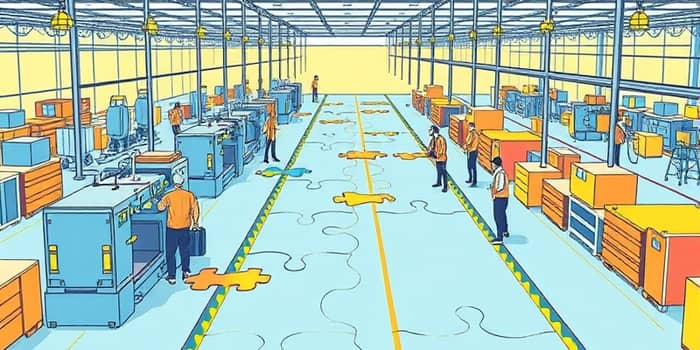

Lean Manufacturing: A Path to Efficiency

Lean manufacturing, pioneered by Toyota in the 1950s, offers a powerful framework to combat waste and boost output. It focuses on eliminating non-value-adding activities and creating seamless flow.

At its core, lean targets seven to eight key wastes, which include overproduction, waiting, and unnecessary motion. By addressing these, businesses can streamline operations and enhance productivity.

- Overproduction: Making more than needed leads to excess inventory.

- Waiting: Idle time between processes reduces efficiency.

- Transportation: Unnecessary movement of materials adds cost.

- Overprocessing: Doing more than required wastes resources.

- Excess Inventory: Tying up capital in unused stock.

- Unnecessary Motion: Poor layout causing wasted effort.

- Defects: Errors that require rework or scrap.

- Unused Talent: Failing to leverage employee skills.

Lean principles empower organizations to transform these weaknesses into strengths. Through continuous improvement, or Kaizen, small daily changes accumulate into significant gains.

Core Principles and Techniques

Implementing lean involves several key steps, each designed to maximize value and minimize waste. Start by identifying what customers truly value, using tools like Value Stream Mapping.

Just-In-Time production ensures items are made only as needed, reducing inventory by 50-90%. Kanban systems signal stock requirements, fostering a pull-based approach that optimizes flow.

- Create Flow: Optimize layouts and standardize work with 5S methods—Sort, Set in Order, Shine, Standardize, Sustain.

- Continuous Improvement: Encourage employee suggestions for small, incremental changes.

- Quality Focus: Integrate checks to prevent defects and reduce rework.

- Employee Engagement: Train workers in problem-solving to boost innovation.

- Technology Integration: Use Manufacturing Execution Systems for data-driven decisions.

These techniques not only cut costs but also enhance Overall Equipment Effectiveness (OEE). By fostering a culture of efficiency, businesses can adapt to changing demands seamlessly.

Implementation Steps for Success

Adopting lean manufacturing requires a structured approach. Begin with a clear plan and comprehensive employee training to build buy-in.

- Develop a Customized Plan: Tailor processes to your organization's unique needs.

- Train Employees: Equip teams with lean tools and mindset.

- Leverage Technology: Integrate systems for real-time monitoring.

- Shift Organizational Culture: Promote collaboration and continuous learning.

- Daily Reflection: Ask questions like, 'Where can we reduce waste today?'

This iterative process ensures that lean becomes embedded in daily operations. Over time, it leads to sustained improvements without significant capital expenditure.

Quantified Benefits and Real-World Impact

The rewards of lean manufacturing are substantial and well-documented. Companies like Ford, Toyota, and Nike have seen dramatic improvements in performance.

- Operating Cost Reduction: Typically 20-30% lower costs.

- Productivity Improvement: Gains of 30-40% in output efficiency.

- Lead Time Reduction: Cuts of 80-90% in delivery times.

- Inventory Reduction: Decreases of 50-90%, freeing up capital.

- Quality Enhancements: Fewer defects and higher customer satisfaction.

- Employee Benefits: Reduced turnover and increased engagement.

Statistics show that 95% of implementers achieve at least a 20% rise in productivity. These benefits translate into competitive advantages and long-term sustainability.

Strategies to Solve the Broader Puzzle

Beyond manufacturing, addressing the productivity puzzle requires holistic strategies. Embed technology across sectors, but pair it with upskilling and institutional reforms.

- Invest in Human Capital: Education and training boost output, similar to software upgrades.

- Increase Capital Stock: Accelerate growth in physical and intangible assets.

- Incentivize Innovation: Policies that reward R&D and process improvements.

- Address Rigidity: Reduce bureaucratic barriers to change.

- Foster Collaboration: Between frontier firms and laggards to spread best practices.

In practice, this means learning from examples like agriculture, where tech shifted labor needs, or frontier firms that leverage organizational changes for outsized gains.

Inspiring Real-World Examples

Success stories abound, demonstrating the transformative power of lean principles. Toyota and Ford achieved significant defect reductions through quality-focused initiatives.

Nike and Amazon used continuous improvement to raise OEE and capacity. Parker Hannifin saw productivity soar while cutting turnover and absenteeism.

These cases highlight that technology adoption coupled with cultural shifts yields the best results. Even in broader economic contexts, firms that embrace change lead the way.

As we navigate the productivity puzzle, the key lies in action. By adopting lean mindsets and investing in efficiency, businesses can turn challenges into opportunities for growth.

References

- https://www.ineteconomics.org/perspectives/blog/which-productivity-puzzle

- https://leanfactoryamerica.com/blog/how-lean-manufacturing-can-boost-your-bottom-line/

- https://www.stlouisfed.org/publications/page-one-economics/2017/03/03/the-productivity-puzzle

- https://www.yourco.io/blog/how-to-improve-manufacturing-productivity

- https://www.mckinsey.com/~/media/mckinsey/featured%20insights/employment%20and%20growth/new%20insights%20into%20the%20slowdown%20in%20us%20productivity%20growth/mgi-the-productivity-puzzle-discussion-paper.ashx

- https://www.sixsigmadaily.com/4-ways-lean-manufacturing-impacts-business-productivity-and-competitiveness/

- https://obr.uk/box/the-productivity-puzzle/

- https://valescoind.com/news/5-lean-manufacturing-principles-to-improve-efficiencies/

- https://www.dawgen.global/the-productivity-puzzle-why-the-world-is-working-harder-for-less/

- https://www.machinemetrics.com/blog/5-lean-manufacturing-system-techniques-to-improve-processes

- https://www.grantthornton.global/en/insights/growthiq/productivity-puzzle/

- https://www.evsm.com/Lean-Manufacturing-and-Continuous-Improvement

- https://project-management.com/what-is-the-productivity-puzzle-and-why-does-it-matter/

- https://www.leanproduction.com/improve-production-today/

- https://www.aicpa-cima.com/resources/download/tackling-the-uk-productivity-puzzle